Infrastructure

LSR Mills boasts world-class infrastructure encompassing advanced steel melting, precision rolling, heat treatment, and comprehensive testing facilities - engineered for excellence at every stage of production.

Steel Melt Shop

- Electric Induction Furnaces: Two furnaces having capacity of 15 Ton & 7 Ton, featuring dual crucibles.

- Ladle Refining Furnace (LRF): Equipped with the latest scada based PLC control for electrode regulation system and argon purging system. to minimize impurities and inclusions in steel making.

- Vacuum Degassing (VD): Installed latest vacuum pumps of Edward UK. Capable of achieving below 1 millibar pressure for reducing gas content in steel up to desired level.

- Continuous Casting Machine: CCM with EMS to make Billets from size 130 mm to 250 mm.

Rolling Mills

- 18 Inch - 14 Inch Mill: Features 3-Hi x 1 stands roughing mill, paired with a 3-Hi 14-inch x 1 stand and a 2-Hi 14-inch x 4 stand configuration.

- 20-Inch Mill: Features 3-Hi and 2-Hi stands for versatile rolling processes.

- Re-Heating Furnaces: Two fully automatic furnaces with 15 MT/hour capacity each, controlled by PLC systems.

- CNC Roll-Making Machine: Ensures precision and minimal tolerance in the final rolled product.

Finishing & Heat Treatment

- MPI Machine: 8.0-meter bed length for magnetic particle inspection.

- Peeling & Reeling Machines: Handles diameters from 18mm to 75mm.

- Annealing & Heat Treatment Furnace:

Our heat treatment facility is equipped with advanced furnaces to ensure consistent and controlled metallurgical properties across all grades and batch sizes.

- Oil-Fired Bell-Type Furnaces: Two furnace with 25-ton capacity and 20-ton capacity, designed for annealing, normalizing, and spheroidising, all equipped with full temperature control systems.

- Electric Furnaces: Two furnaces with 20-ton capacity each, suitable for annealing, normalizing, and spheroidising, featuring precise digital temperature control systems.

- LPG Gas-Fired Furnace: One furnace with 40-ton capacity with fully automised burners designed for efficient and controlled annealing operations.

- Bar straightening Machine: 6 machines for diameters ranging from 12mm to 100mm.

- Hydraulic Bar straightening Machine: 2 hydraulic machines for diameters from 80mm to 160mm.

- Bandsaw Cutting Machines: Six machines capable of cutting diameters from 25mm to 450mm.

Inspection & Testing Facilities

- Spectrometer

- Mobile Spectrometers

- Impact Testing Machine

- Ultrasonic Flaw Detector

- Universal Testing Machine

- Jominy Testing

- Hardness Testing

- Chemical Laboratory

- Metallurgical Microscope

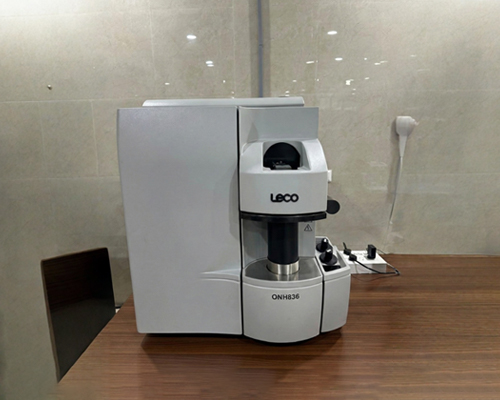

- Gas Analyser (LECO)